Since 2008

Factory Direct Support customization

We have rich machining production experience, , strictly control the quality of production process, and have a perfect qualitymanagement system. Guarantee the quality and delivery time of products

We have lathes, milling machines, machining centers, wire cutting, surface grinding machines, cylindrical grinding machines, etc., and rich technological processes, which can meet the processing of various complex parts

Product Center

Baghouses Dust Collector

Pulse Jet Baghouses Dust Collector are the most common and most efficient type of dust collector. Within a baghouse dust collector, a fan creates a vacuum, forcing contaminated air through fabric filters located in a bag. Applicable: machinery, metallurgy, rubber, flour, chemical, pharmaceutical, carbon, building materials, mining and other units. in various industries.

Air volume (m3/h)

2000-110000(m3/h)

Filter area: (m2)

36-960 (m2)

Main product classification

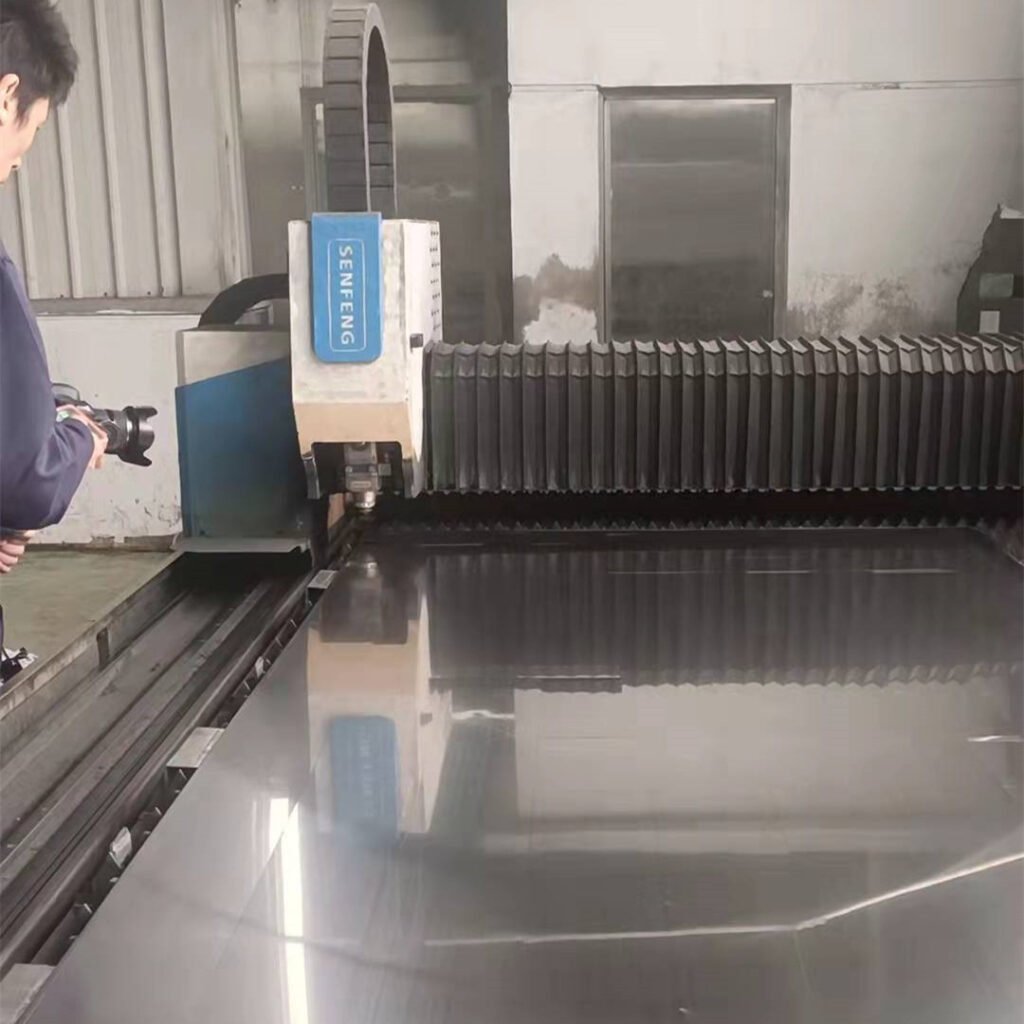

CNC process flow

Raw material

Rough machining

Semi finishing

Precision machining

Introduction:Pulse Jet Baghouses Dust Collector are the most common and most efficient type of dust collector. Within a baghouse dust collector, a fan creates a vacuum, forcing contaminated air through fabric filters located in a bag. The fabric filters catch the particles, allowing clean air to exit the machine’s outlet while dust particles settle to the bottom of the machine’s chamber.

The most common variations of baghouse dust collectors are distinguished by the method they use to clean the filter bags. They include shaker dust collectors, which physically shakes filter bags at intervals to remove dust buildup, reverse air dust collectors, which temporarily reverse air flow within the dust collector to reduce dust buildup, and jet dust collectors, which utilize jets of air to reduce dirt buildup in the fabric filters.

System composition:1,Upper box is includes cover plate and air outlet. 2,Middle box is includes perforated plate, filter frame, sock and venture. 3,Under box is includes ash hopper, air intake and access door Jetting system contains control valve, pulse electromagnetic value, injection pipe and air

Working Principle: During the dust gas goes into middle box and under box, the dust can be attached to filter bag and outgoing gas after going through venture and upper box. With the increasing of dust, press loss for dust bag is increased, which will fed back to controller. Receiving and issuing commands, the controller will touch off every pulse valve to make gas erupts from each jetting hole, then pass a venture tube and spray into corresponding filter bag. The filter bag expands rapidly under instantaneous reaction of airflow, dust fallen off of the filter bag, so the filter bag can be recycled.

The baghouse filter is composed and configured on the base of type of use and the specific requirements of the client. The Pulse Jet Cleaning System is managed by a PLC with a sensor that reads the pressure drop of the filtering elements encouraging minor compressed air consumption and greater duration of the bags. The pre-chamber recovers the biggest powder particles, safeguarding the baghouses from excess loads of pollutants and guaranteeing longer duration. The hopper includes a screw conveyor and rotary valves to continuously unload the filtered powder. The ladder and the railings allow convenient access to the roof of the filter to change and maintain the filtering parts.

Great strength

Professional dust collectors manufacturer since 2008,more than 1000 customers choose

Reliable quality

Implement the strictest QC system to manage ourproduction processes.

Reasable price

Cost-effective price. Scientific cost control system to manage all process cost.

First-class service

Provide the best customized solutions. Offer life-long after sales service.

One-stop

Provides a wide range of products to satisfy customers with one-stop purchase.

Talent team

Own Top-class professional and exprerienced R&D, manufacturing and sales team.

Quick shipping

The first 7 days delivery manufacturer of dust collectors.

Trade assurance

Trade Assurance protects online orders when payment is made.